6Pin 36mm 12V 24V 10000RPM BLDC Motor Inner Rotor Brushless DC Motor With Built-In Driver

6Pin 36mm 12V 24V 10000RPM BLDC Motor Inner Rotor Brushless DC Motor With Built-In Driver

Quick Detail:

Inner Rotor Brushless Motor

High Efficiency 80%~90%

Built-in Driver

Adjustable Rated Voltage

Controllable Motor Rotation(CW/CCW)

Permanent Magnet

Ball Bearing & Oil Bearing Customized

Low Noise

Life Span 10000~20000hrs(Based on the actual operation of the motor)

1 Year Warranty

ODM,OEM Service

Specification

| Model | DBL3626I |

| Size | Diam 36mm * L 26mm |

| Rated Voltage | 24V DC (Customized) |

| Speed | 8927rpm (Customized) |

| Rated Torque | 91.3 g.cm |

| Output | Approx 2W~15W |

| Shaft Diameter | 4mm |

| Power Efficiency | 80~90% |

| Ball Bearing or Oil Bearing | Can be available as customized |

| Direction of Rotation | CCW / CW |

| Noise | 30~60db |

| Working Temperature | -10℃ ~ +70℃(25℃best) |

| Life span | 10000~20000hrs(Based on the actual operation of the motor) |

Motor Terminations

| No. | Pin Arrangement |

| 1 | VCC |

| 2 | FG |

| 3 | CW/CCW |

| 4 | GND |

| 5 | PWM |

| 6 | BRAKE |

Features

This brushless motor has a built-in driver, which means it can be easily controlled and requires fewer components. The driver provides accurate speed control and torque output, making it suitable for various precision applications. The brushless motor features a high efficiency of 80% to 90%, which ensures low power consumption and high performance. It is suitable for various high-load applications such as industrial equipment, construction machinery, and transportation vehicles. The brushless motor has a low noise level, ensuring quiet operation. It has a long lifespan of 10,000 to 20,000 hours, which means it can provide stable performance for a long time. The brushless motor has a ball bearing and oil bearing option, which ensures smooth rotation and longevity. It also features adjustable rated voltage and controllable motor rotation (clockwise/counterclockwise), making it suitable for various applications. The brushless motor is backed by a one-year warranty, ensuring peace of mind for customers. Additionally, the company provides ODM and OEM services to customize the brushless motor according to specific requirements.

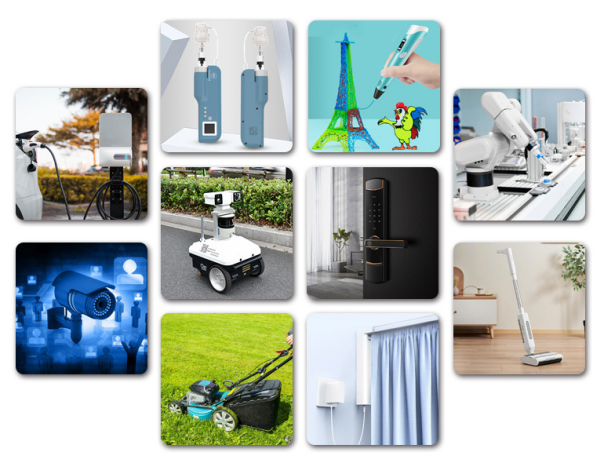

Application:

The Brushless dc motors are widely used in various fields, including personal care, household appliances, power tools, commercial equipment, medical equipment,etc. They are used as drive motors in these scenarios, providing high efficiency, high precision, and long life, exhibiting excellent performance.

Packaging

Packing:Foam Box+ Export Carton

Delivery:

Shipping Time:5-7 working days for samples.

Shipping Channel:We can check the shipping fee and channel with our agents if needed.

FAQ

1.What is a Brushless DC Motor?

A: The brushless DC motor is a type of electric motor that uses permanent magnets and electronic commutation to convert electrical energy into mechanical energy. They eliminate the need for brushes and commutators, which are commonly found in brushed DC motors.

2.How does a Brushless DC Motor work?

A: Brushless DC motors work by using an electronic controller to commutate the motor's stator coils. The controller senses the position of the rotor and switches the coils' polarity accordingly, causing the rotor to rotate. The controller can also regulate the speed by varying the amount of current sent to the coils.

3.What are the advantages of Brushless DC Motors?

A: Brushless DC motors offer several advantages over brushed DC motors. These include: higher efficiency, longer lifespan, lower maintenance requirements, quieter operation, and the ability to operate over a wider range of speeds.

4.What are the common applications for Brushless DC Motors?

A: Brushless DC motors are commonly used in a variety of applications where high efficiency and reliability are required, including: household appliances, pumps and fans, electric vehicles, industrial automation, and medical equipment.

5.What is the difference between a Brushless DC Motor and a Brushed DC Motor?

A: Brushless DC motors eliminate the need for brushes and commutators by using electronic commutation instead. This allows them to operate more efficiently and with lower maintenance requirements than brushed DC motors.

6.What is meant by 'torque density' in Brushless DC Motors?

A: Torque density in brushless DC motors refers to the amount of torque produced per unit volume of the motor. It is a measure of how powerful a motor is for its size and is an important factor in selecting a brushless DC motor for a specific application.

7.What is the role of Hall-effect sensors in Brushless DC Motors?

A: Hall-effect sensors are used in brushless DC motors to sense the position of the rotor and provide feedback to the electronic controller. The controller uses this feedback to commutate the motor's coils properly and achieve smooth rotation of the rotor.

8.What are the maintenance requirements for Brushless DC Motors?

A: Brushless DC motors require relatively low maintenance compared to brushed DC motors. Typical maintenance tasks may include regular cleaning and filtering of the motor's internal components, replacement of wear-prone parts like bearings and belts, and checking electrical connections for tightness and corrosion. However, specific maintenance requirements depend on the application and type of brushless DC motor being used.

9.How long is the delivery ,producing and shipping?

A: Deliver time depends on the quantity you order. usually it takes 15-25 working days.

10.How to order?

A: send us inquiry → receive our quotation → negotiate details → confirm the sample → sign contract/deposit → mass production →cargo ready → balance/delivery → further cooperation